Visualize Internal Structures

"Non-Destructively" and in "High Resolution"

Government of India (DPIIT)

Launched by the Indian Government's Department for Promotion of Industry and Internal Trade (DPIIT) in 2014, Make in India is a national initiative promoting domestic manufacturing and investment. It represents policy and investment support framework to strengthen India's manufacturing sector.

*This is a government initiative promoting manufacturing, not a product certification.

Atomic Energy Regulatory Board (India)

AERB is India's regulatory authority for ionizing radiation and nuclear energy safety. It oversees medical and industrial X-ray equipment, radioisotope applications, and radiation therapy facilities, ensuring the highest safety standards for radiation-related operations.

Indian Society for Non-Destructive Testing

NOVSOL COMCO INDIA is a member of the Indian Society for Non-Destructive Testing (ISNT), India's premier professional body for NDT, promoting advancement in non-destructive testing technologies.

We are offering a special campaign where the first sample scan is free of charge.

Simply send us your product sample, and you can experience high-performance CT scanning at no cost.

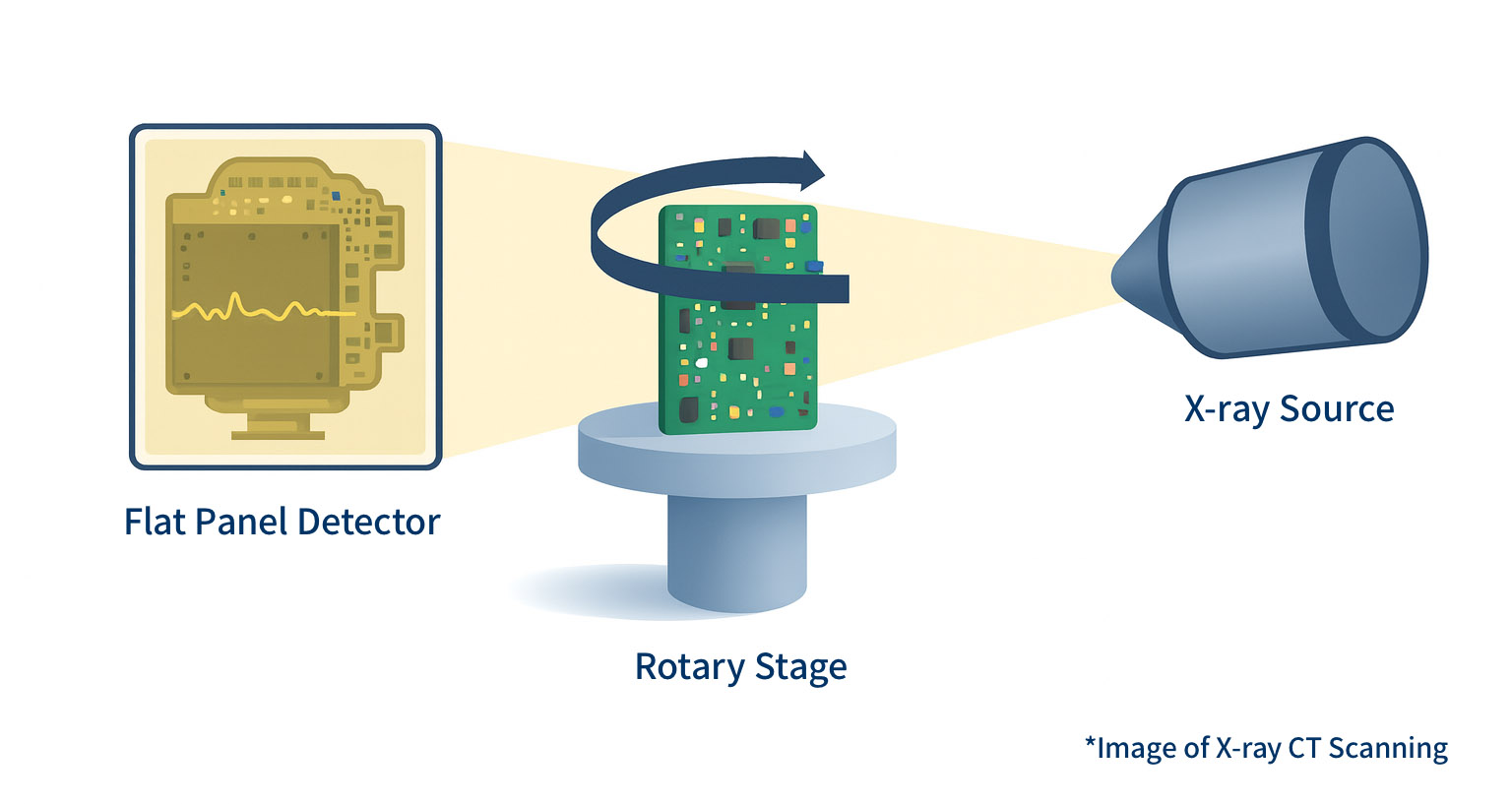

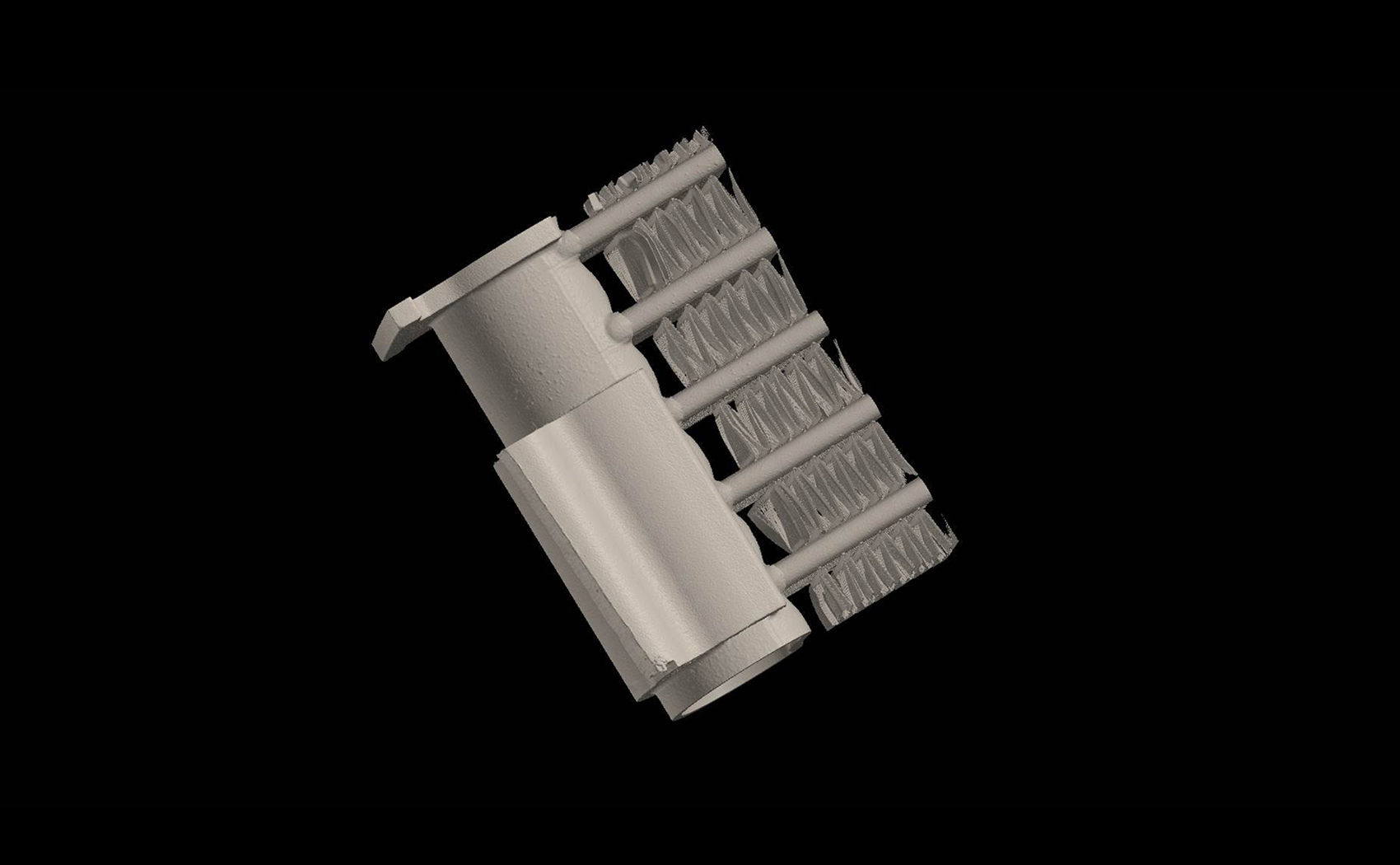

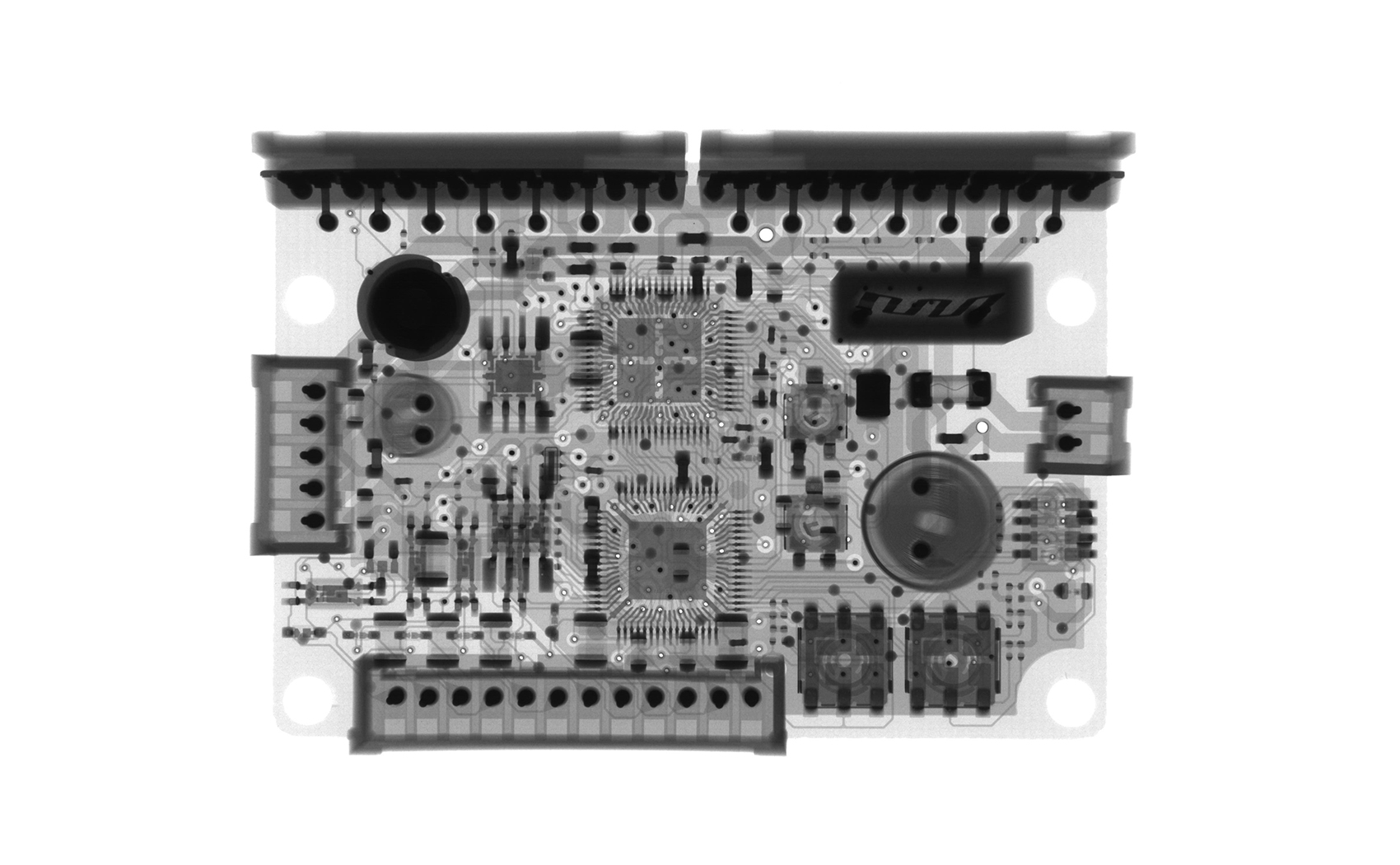

X-rays are used to scan the product as it rotates 360 degrees,

and the resulting images are reconstructed into a 3D model.

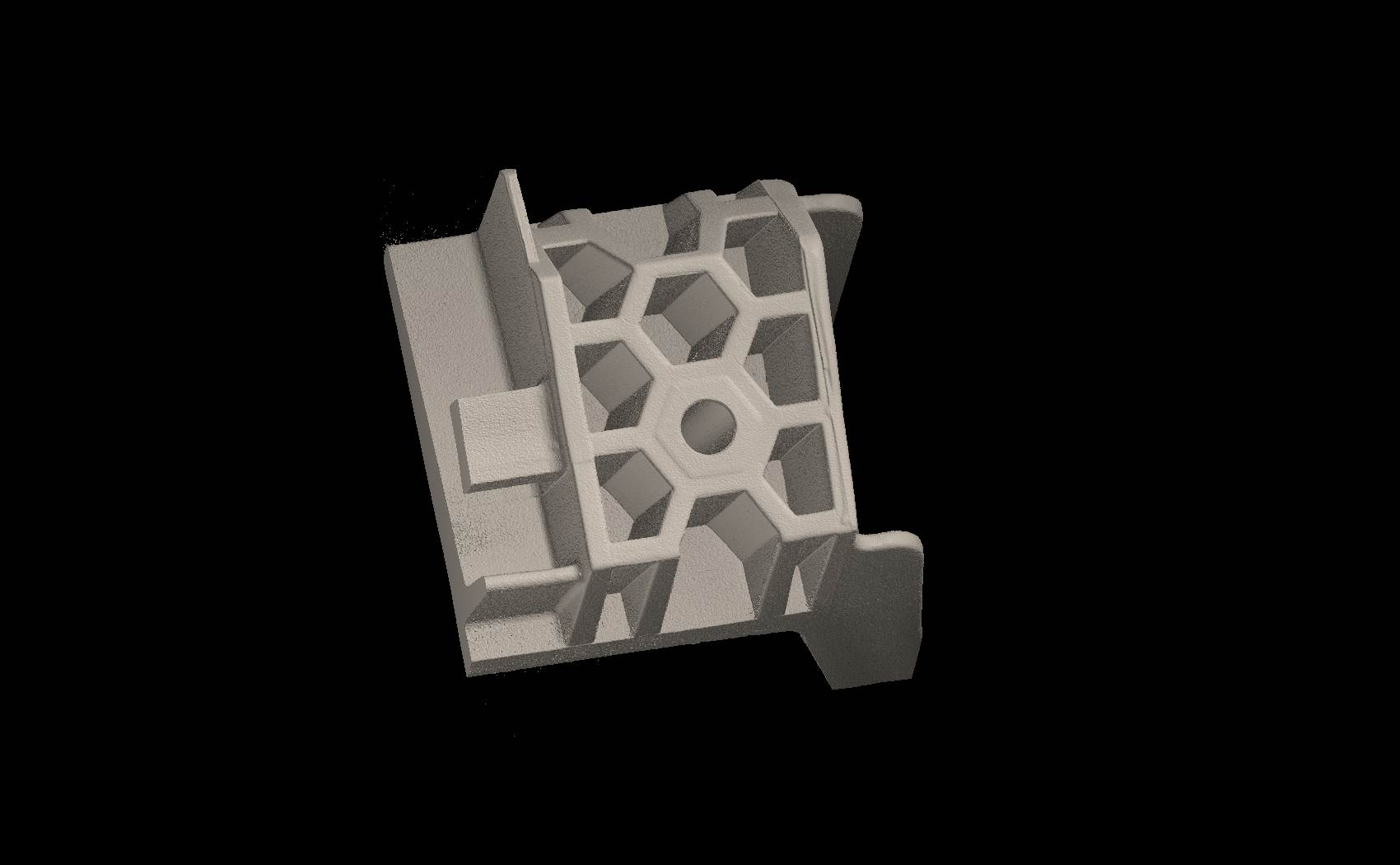

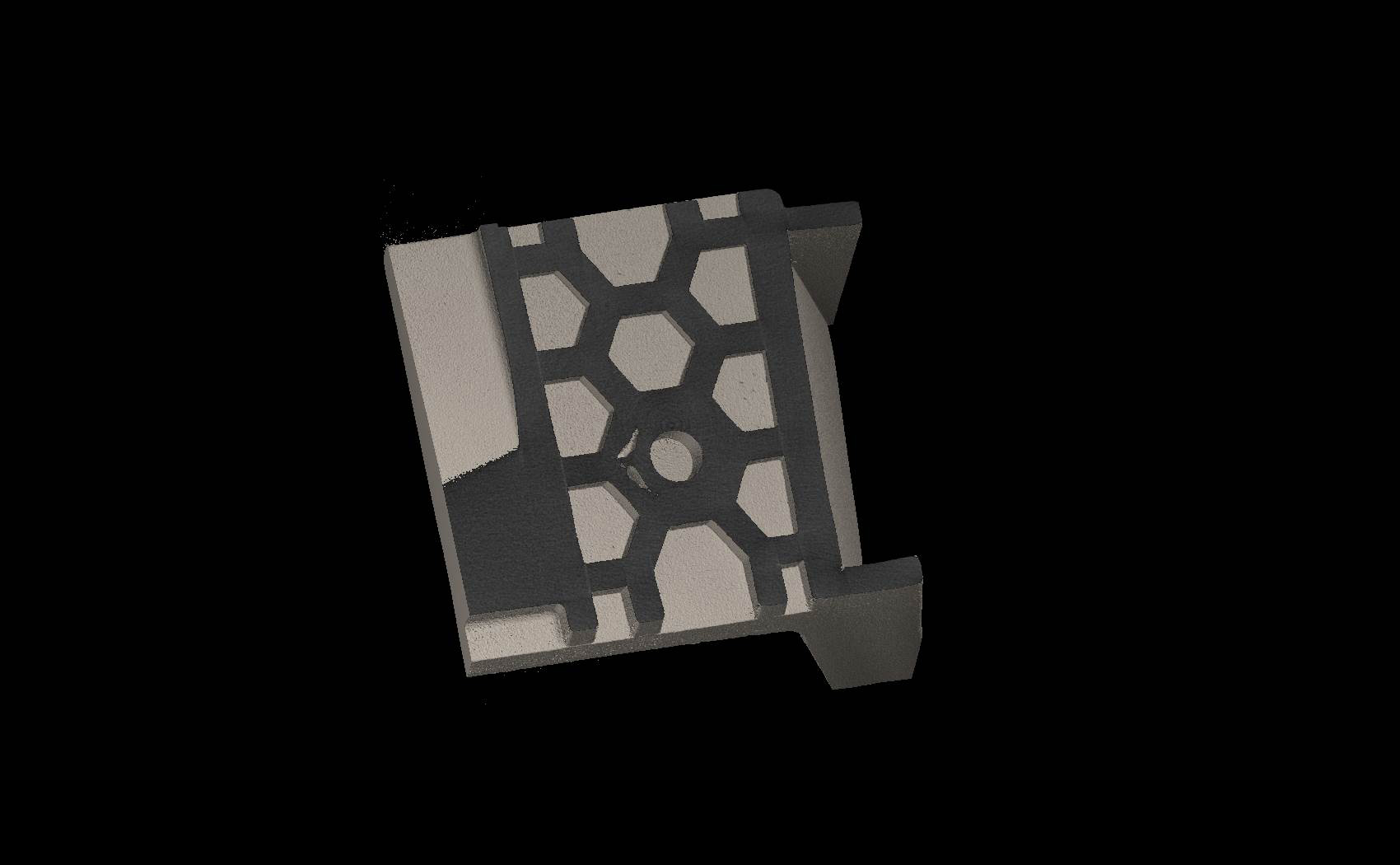

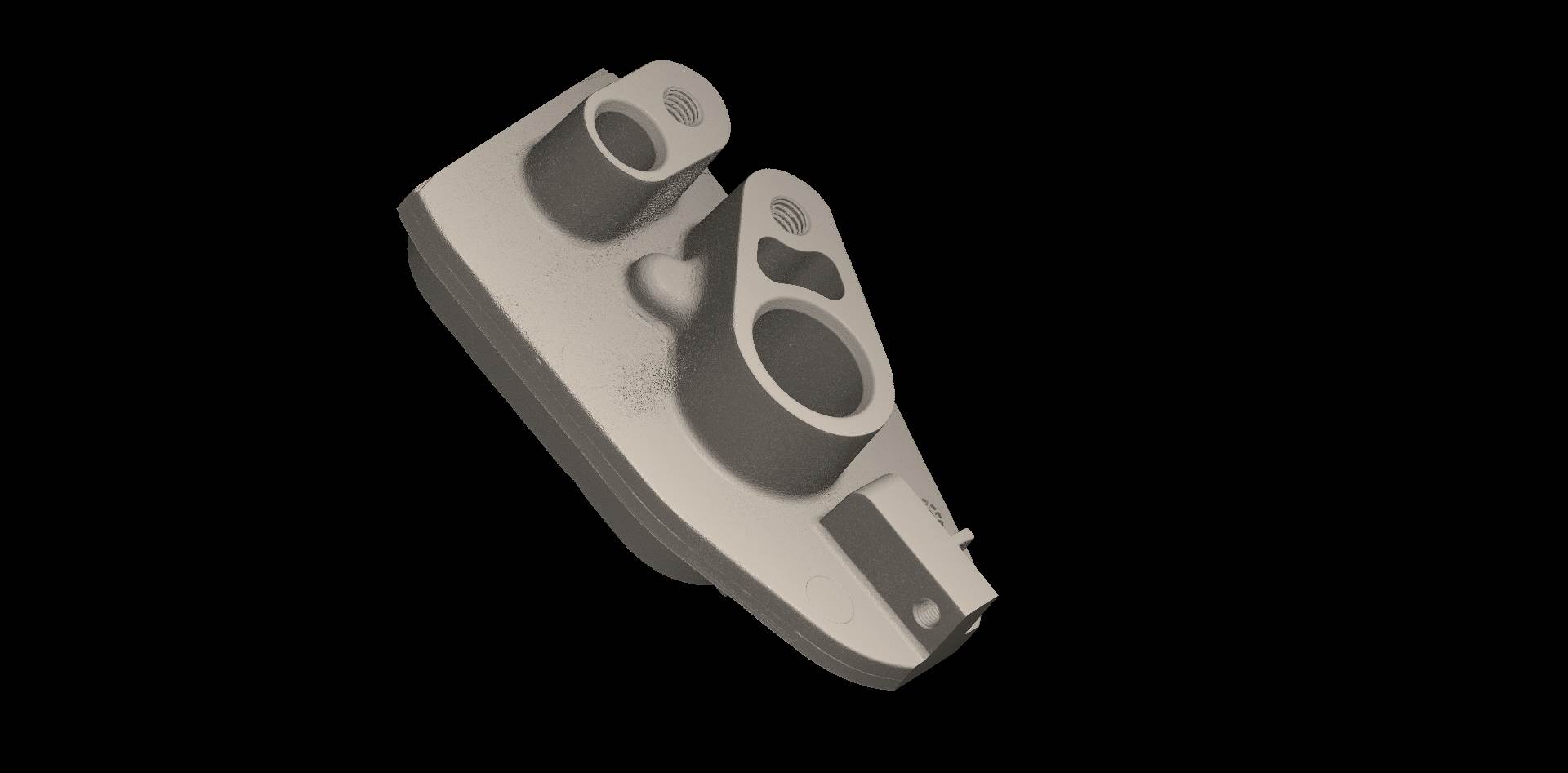

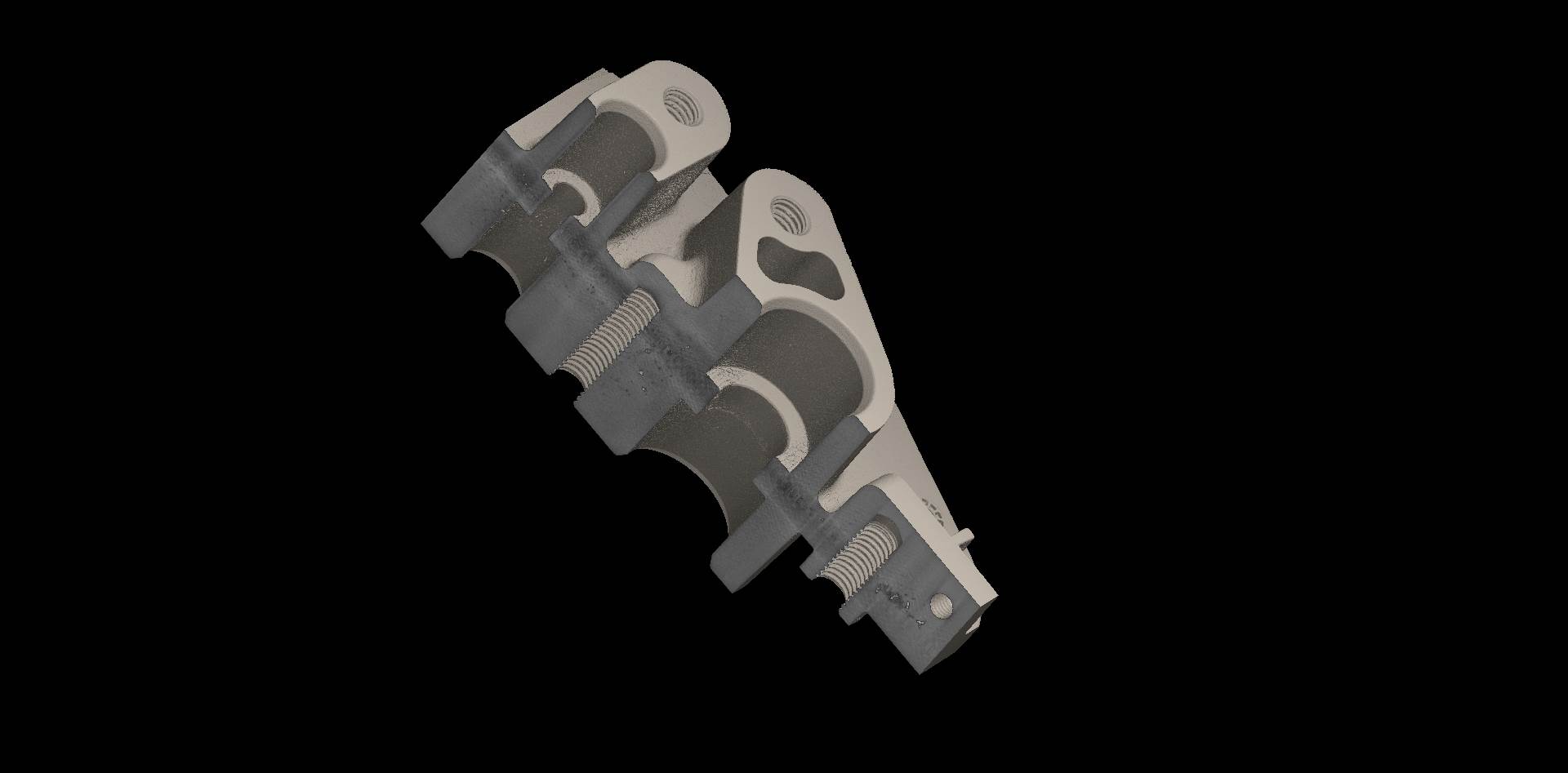

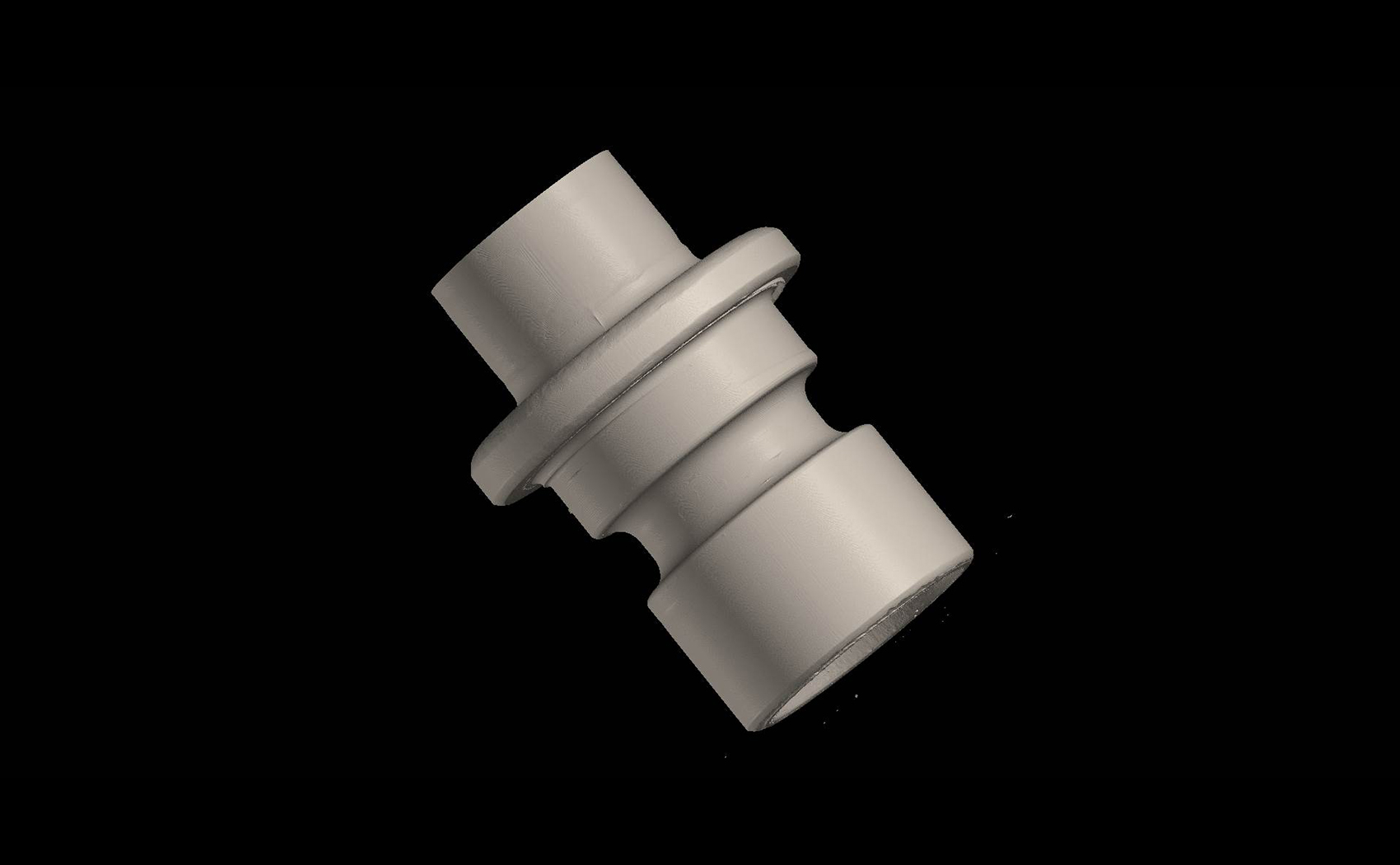

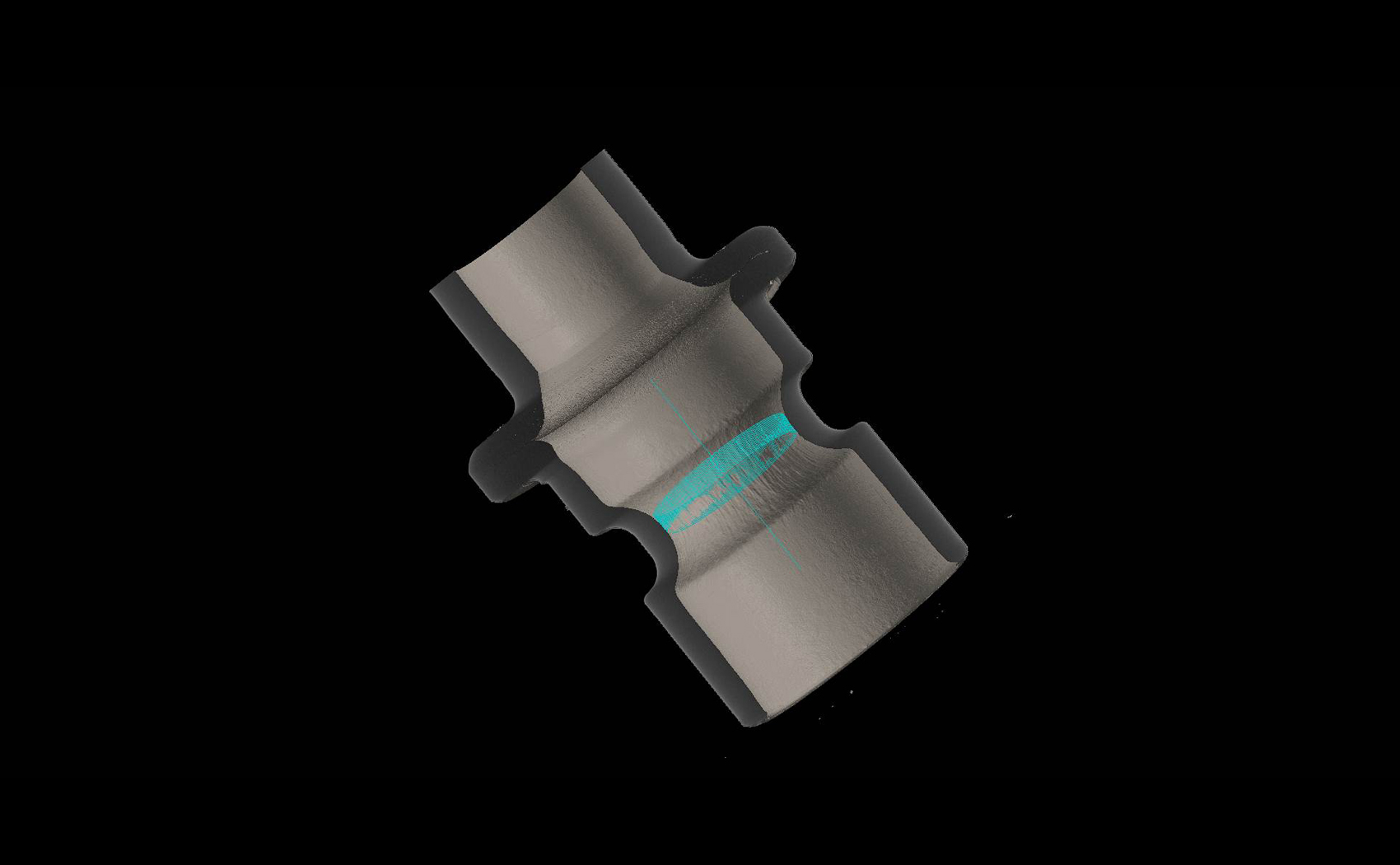

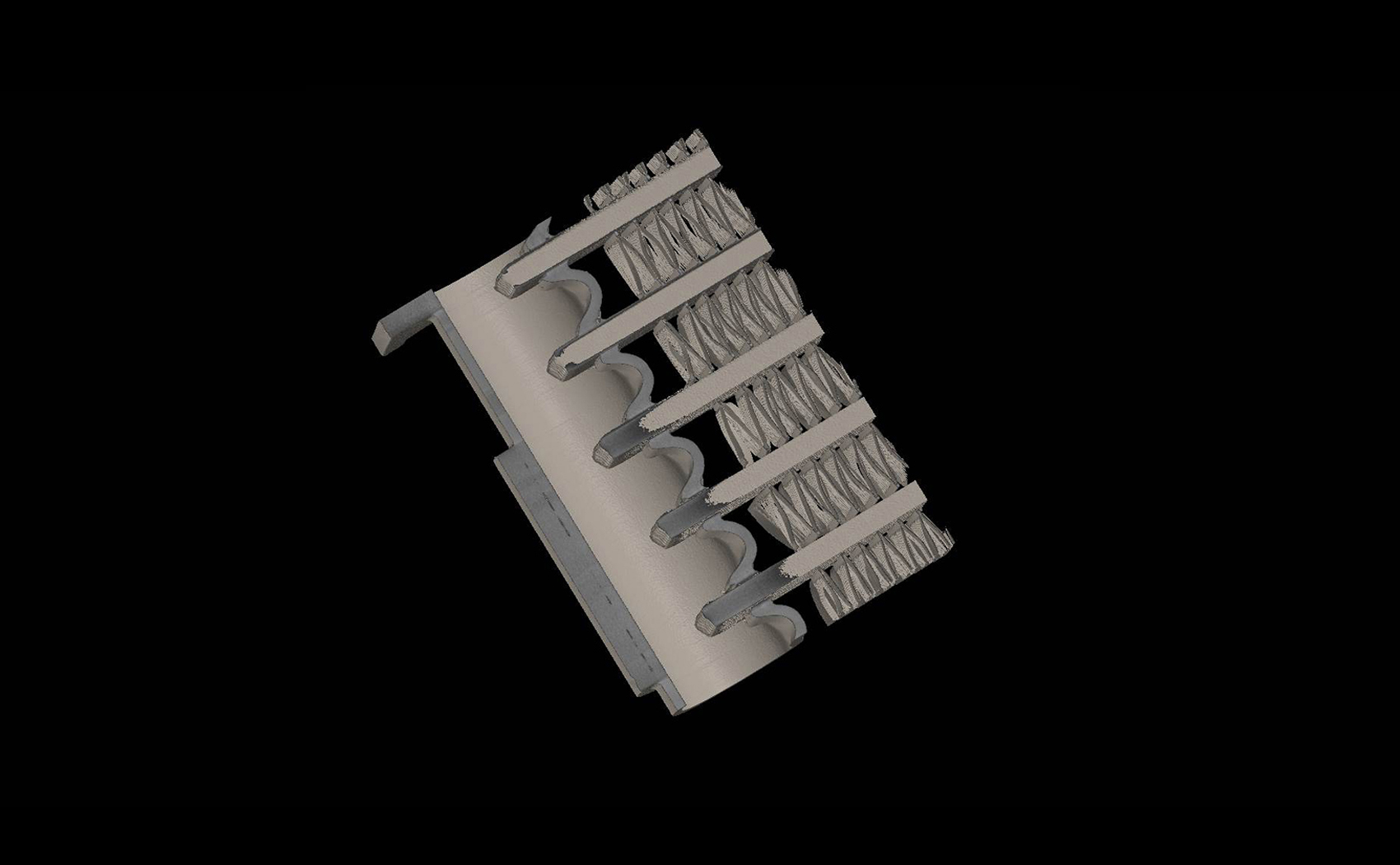

Reconstructed 3D data allows you to visualize internal structures

and any cross-section of products, enabling inspection and observation without cutting.

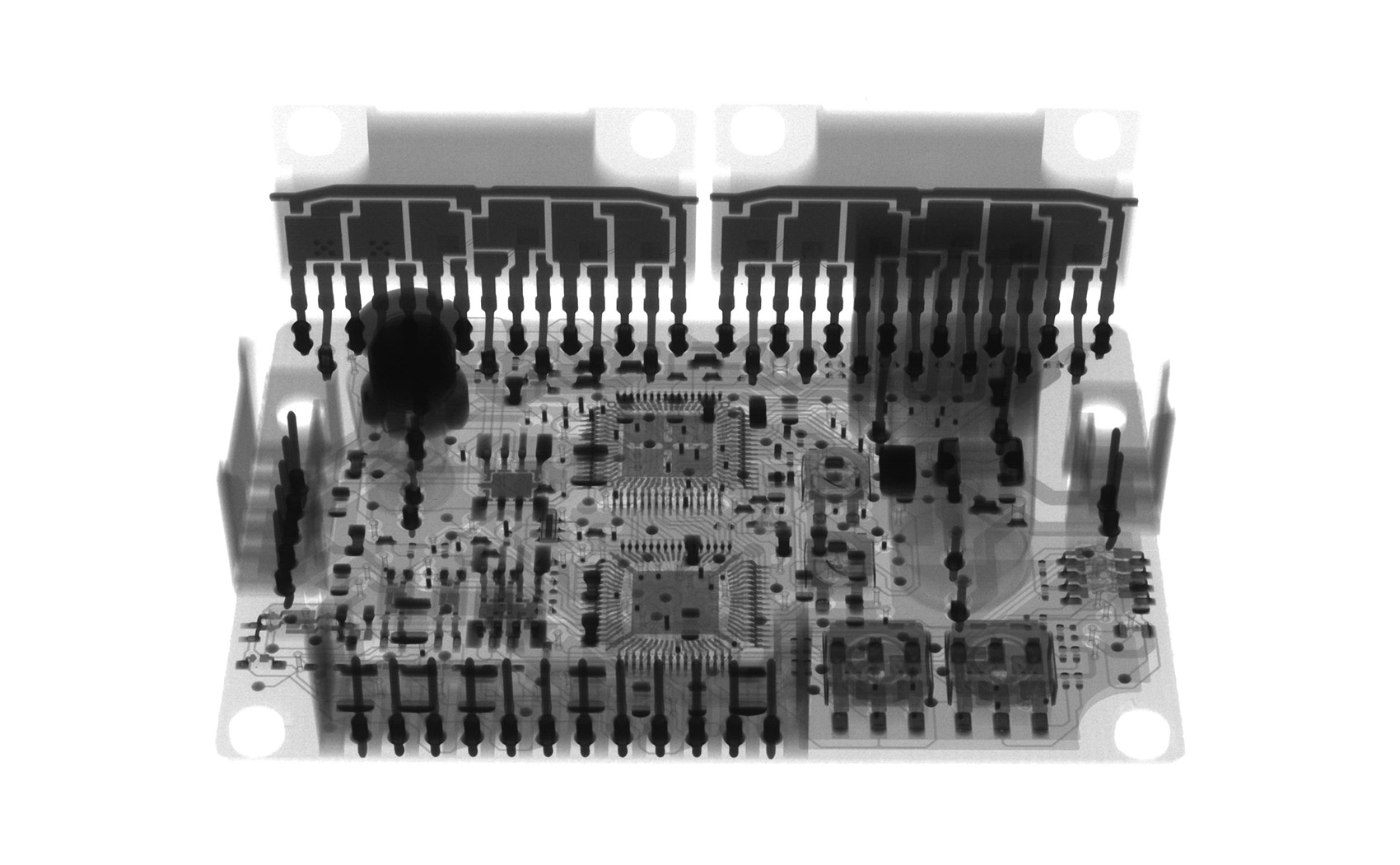

CT scan data enables quality control and defect analysis,

leading to higher product quality and improved production efficiency.

Non-destructive inspection lets you visualize internal defects, voids, and filling conditions of resin products, supporting mold optimization and defect analysis.

Casting defects such as porosity, cracks, and joint conditions can be visualized in 3D, enabling precise inspection for quality control and process improvement.

Areas that would normally require cutting for inspection can be visualized non-destructively, and cylinders or spheres can be fitted to measure diameters accurately.

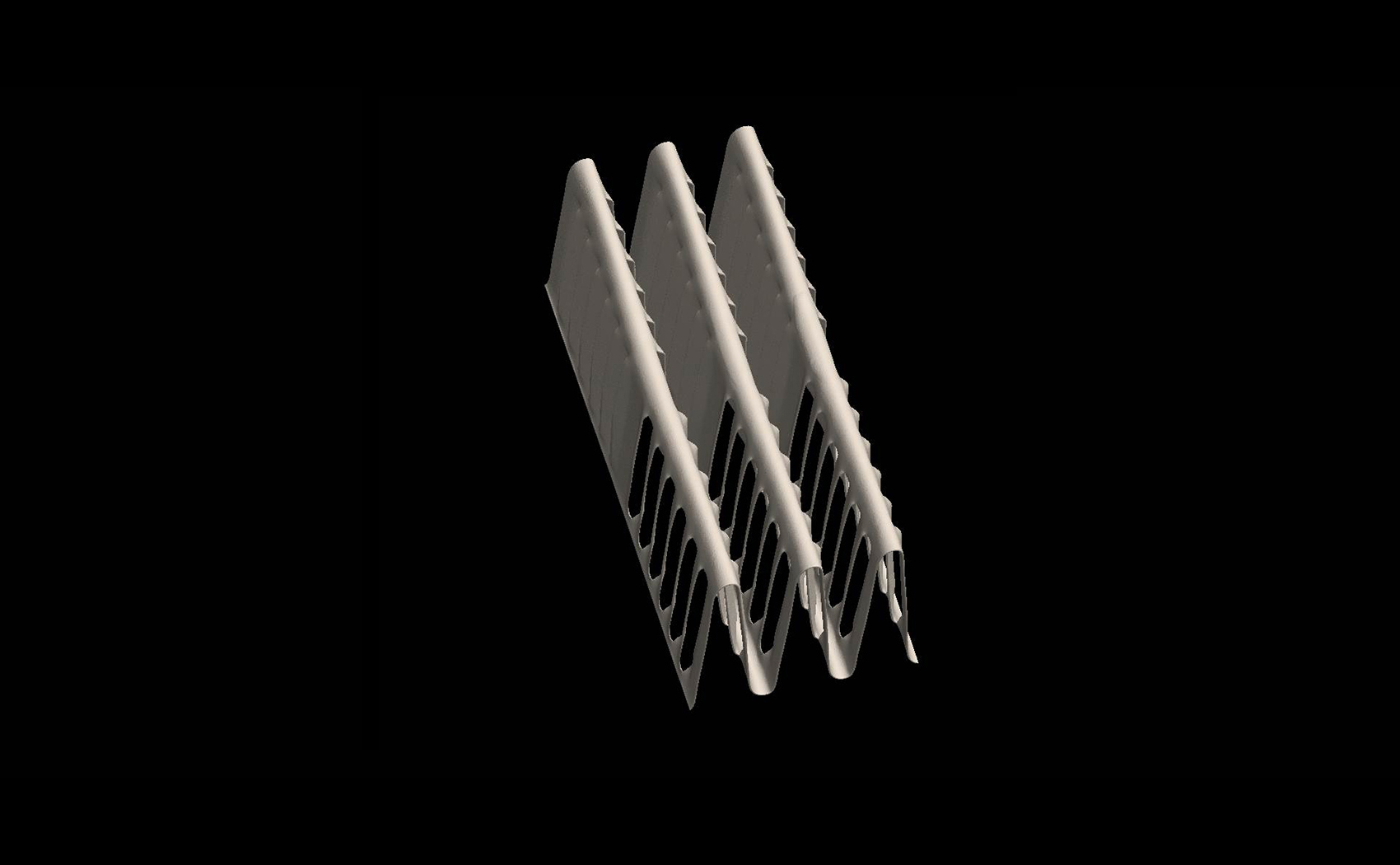

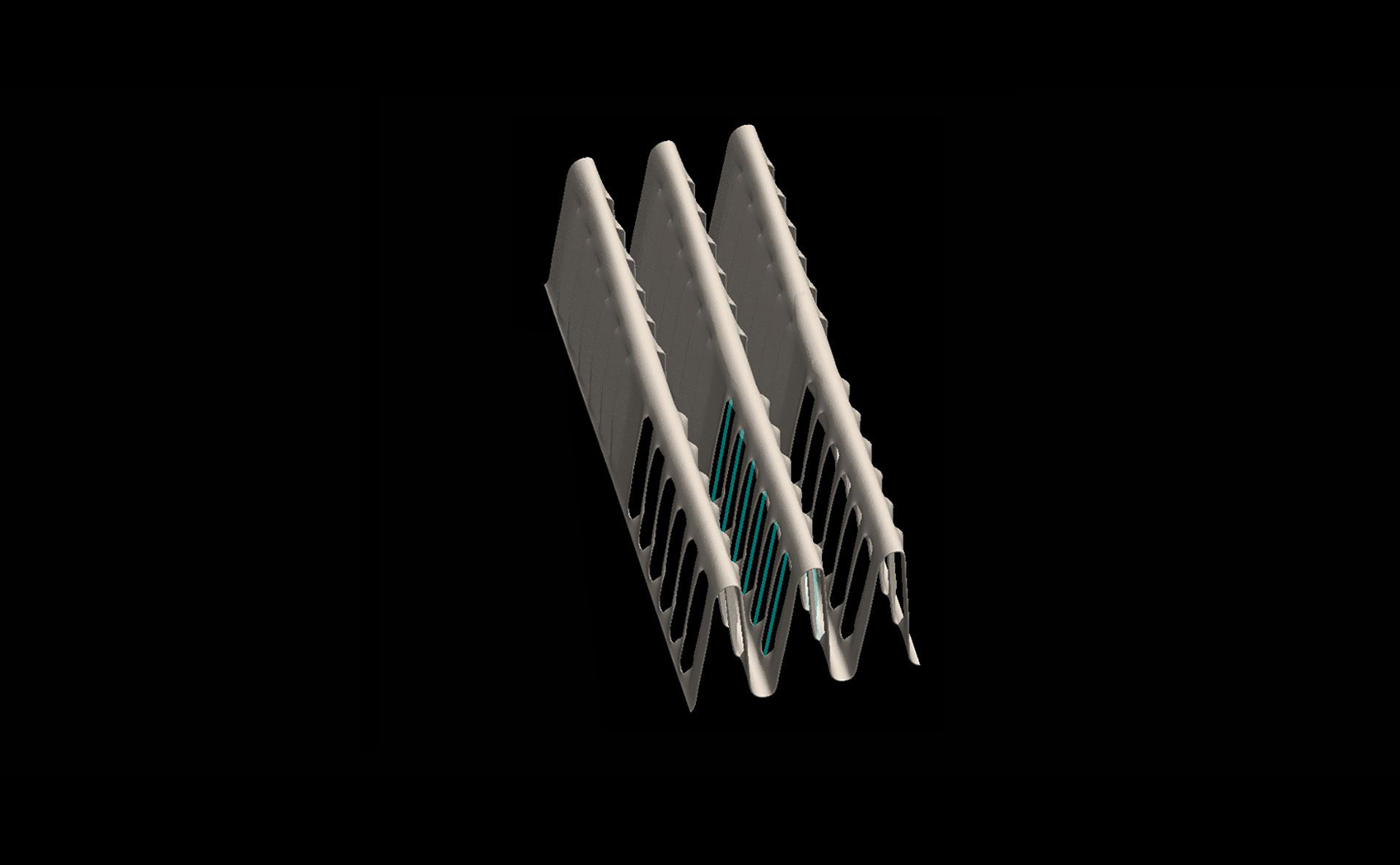

Corrugated fins used in heat exchangers can be imaged in their formed state, allowing automatic measurement of fin height and louver cut length and angle. For flat tubes, measuring the center gap of B Tubes, and the radius at both ends compared with the design values can be automatically analyzed. This reduces the need for cutting, resin filling, or polishing, eliminating operator-induced variability.

Ideal for in-depth inspections after leak testing, enabling accurate checks of brazed joints and defect detection. With no deformation from resin filling or polishing, it provides more reliable analysis of brazing defects.

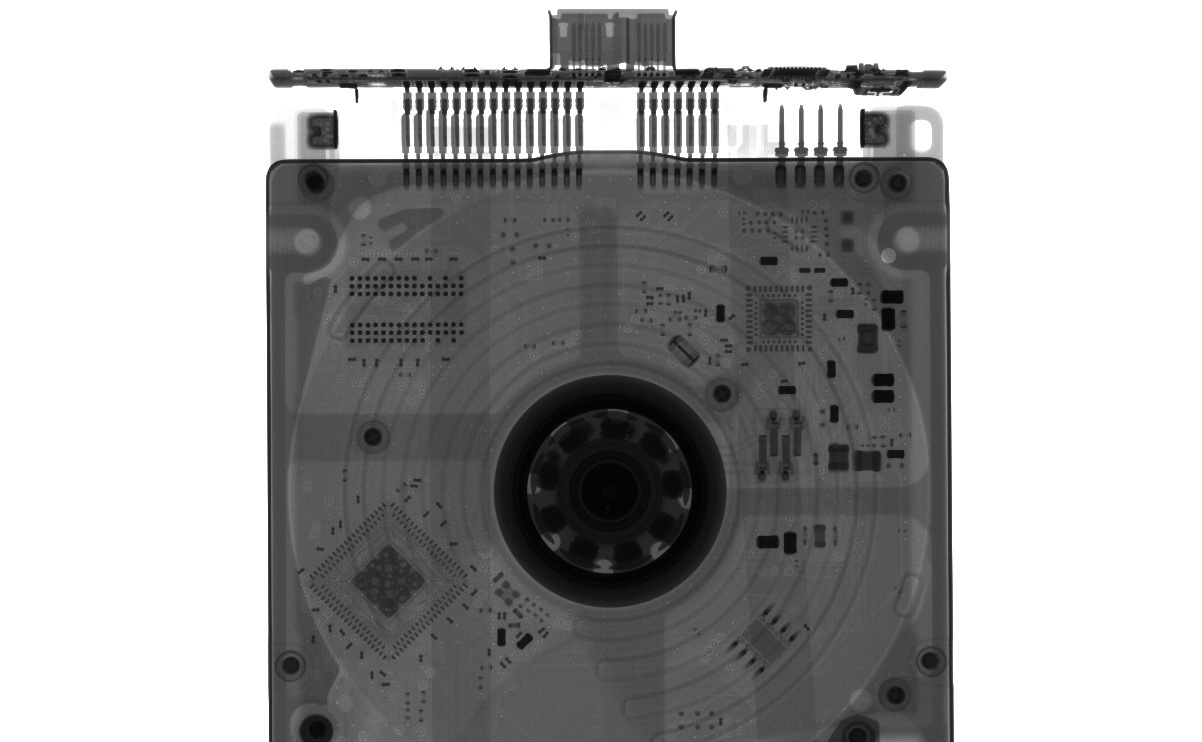

With X-rays irradiated, the system enables visualization of the internal structure,

allowing non-destructive inspection in a shorter time compared to 3D scanning.

It also allows saving fluoroscopic 2D images at any desired position.

| Specifications | X-CROSS 90 |

|---|---|

| X-ray Tube | |

| - Tube Voltage | 20kV - 90kV |

| - Tube Current | 10µA - 200µA |

| - Maximum Output | 8W |

| Flat Panel Detector | |

| - Number of Total Pixels | 2940 × 2304 |

| - Photosensitive Area | 146mm × 114mm |

| Maximum Sample Size (Settable in the device) |

Φ180mm × H150mm |

| Maximum Sample Weight (Settable in the device) |

2kg |

| Scan Conditions | |

| Approximate Scan Resolution and Range |

10µm: H30mm × W20mm ~ 30µm: H90mm × W70mm |

Both the standard model used for services and customized models from above specifications can be manufactured and supplied. Feel free to contact us including inspection services.

Maximum sample size: φ180 mm × H150 mm. Larger samples must be cut before submission. Actual scannable size depends on resolution. X-ray penetration is typically up to 30 mm for aluminum and 60 mm for plastics, depending on shape. For stainless steel, iron, or copper samples, please contact us for consultation.

Dimensional measurements are available, but values are for reference only and not guaranteed.

Yes, it is possible. Customers can bring in samples and specify the scan conditions for on-site observation. This service is available in Japan or India. Please contact us for further details.

The free trial campaign is limited to one sample and one scan per company. For more details, please contact us.

Please provide details about the product, such as size, material, and the defects or inspection items to be checked. Sharing this information in advance allows us to provide more accurate inspection results.

Please feel free to contact us. We accept inquiries by phone or email.

After confirming the sample and inspection details, we will provide a cost quotation if you decide to proceed with the inspection.

*Free trial is available now.

Send your product samples to us. Shipping costs are borne by the customer.

Once the order is placed, we will perform the CT scan. Scan time varies by sample, usually between 10 minutes and 2 hours.

Upon request, we analyze the scan data and prepare a report.

We provide cross-sectional images, videos, analysis reports, and other requested deliverables.

For sample scan requests, technical questions, or quotations, please feel free to contact us.

92-1 Matsuba, Takaoka, Toyota, Aichi, 473-0933, Japan

+81-565-51-1111

SEDMIDOMKY 457/4, 101 00 Prague 10, Czech Republic

+420-222-352-820

1105 Myatt Madison, TN37115 USA

+1-615-860-7773

899/26 Moo 21 Soi Chongsiri Parkland, Klong Ar-Zeer Rd., Bangpleeyai, Bangplee, Samutprakarn, Thailand 10540

+66(0)2-313-3774

NO.445/1 (305/1), 6th FLR, GUNA COMPLEX, ANNA SALAI, Teynampet, Chennai, Chennai-600018, Tamil Nadu, India

Your inquiry has been received.

Our team will review your request and contact you shortly.

Thank you for your patience.

*A confirmation email has been sent to the email address you provided.

If you do not receive it, please check your spam folder.